Overall Value

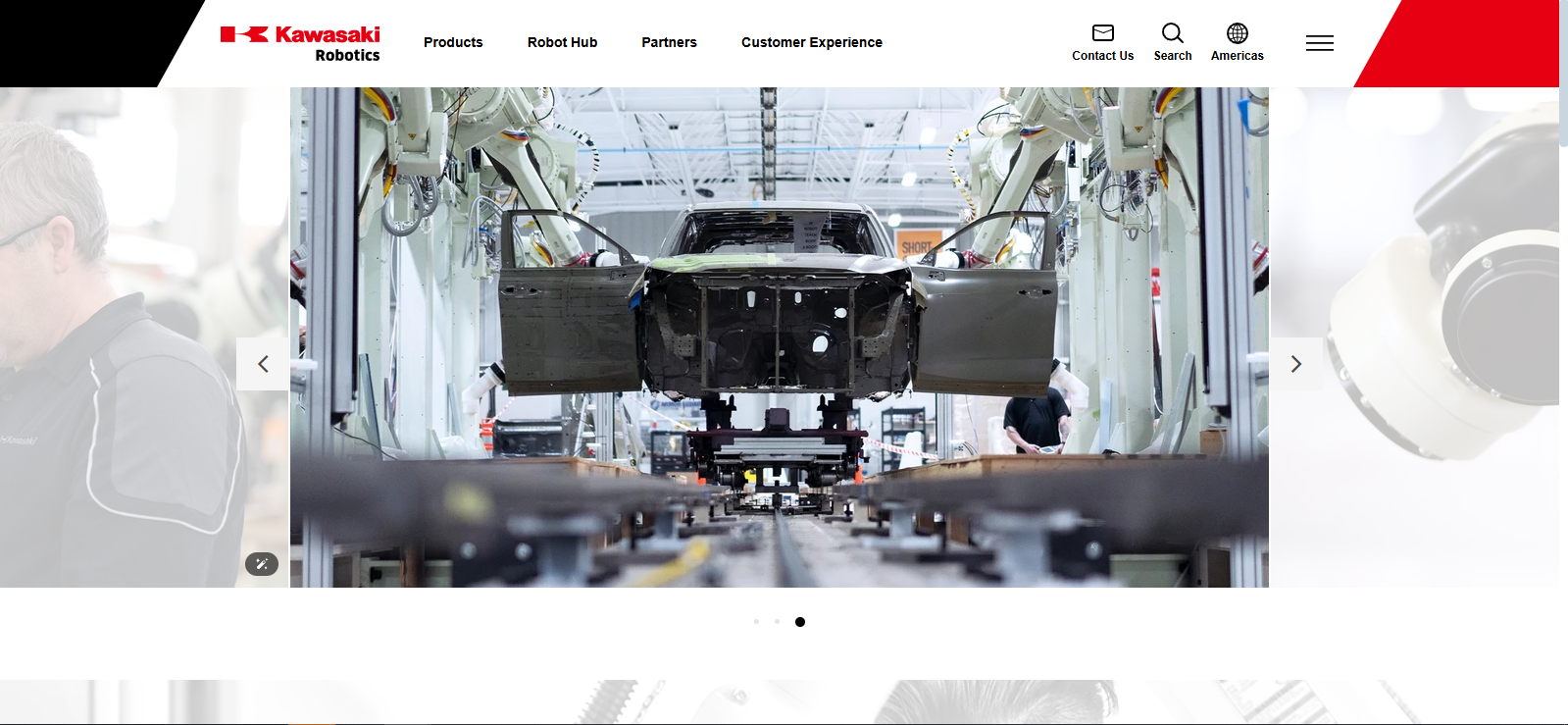

CORLEO Kawasaki bridges advanced robotics with ease of use. Whether you’re automating a single task or an entire plant, it offers powerful, scalable systems designed for performance, safety, and flexibility. With plug-and-play setups, intuitive programming interfaces, and seamless integration into existing workflows, it helps teams of any size deploy robotics with confidence.

Features

• Collaborative and industrial robot arms for diverse applications

• Intuitive block-based or code-based programming options

• AI-powered vision and object recognition for smarter workflows

• Seamless integration with PLCs, SCADA, and MES systems

• Safety-certified systems with real-time obstacle detection

• Remote monitoring, diagnostics, and firmware updates

• Training support and extensive documentation for fast onboarding

• Flexible deployment—from single-arm setups to full automation cells

Use Cases

- Automate repetitive assembly or packaging tasks

- Perform high-speed pick-and-place with precision

- Enable smart inspection using integrated vision systems

- Reduce human error in welding, gluing, or palletizing

- Upgrade legacy lines with modern robotics and software

- Create scalable robotic workflows for 24/7 operations

Technical Specifications

- Supports 6-axis, SCARA, and dual-arm robotic models

- Payload capacities from 3 kg to 150 kg

- High-precision movement with ±0.03mm repeatability

- Compatible with ROS, Python SDK, and proprietary CORL Studio

- Built-in safety protocols with ISO-certified compliance

- Industrial I/O compatibility (EtherNet/IP, EtherCAT, Modbus)

- Cloud-based monitoring and analytics via CORL EdgeConnect

Supercharge your production with CORLEO Kawasaki Explore automation kits, robotics platforms, and AI-integrated solutions

Supercharge your production with CORLEO Kawasaki Explore automation kits, robotics platforms, and AI-integrated solutions

FAQs

Yes! CORLEO offers scalable solutions, from single-arm setups for SMEs to full factory automation for enterprises.

No. With block-based visual programming and step-by-step guides, anyone can set up and run robots—no coding required.

Absolutely. CORLEO systems are designed to work with standard PLCs, conveyors, and industrial protocols.

CORL EdgeConnect ensures data encryption, user authentication, and enterprise-grade compliance for secure factory ops.

CORLEO Kawasaki makes factory automation smarter, not harder. Whether you’re building your first robotic workstation or scaling up production lines, CORLEO delivers precision hardware and intelligent software in one powerful package. With trusted support, flexible deployment, and industrial reliability, it’s your go-to robotics partner.

Conclusion

Mobile ALOHA pushes robotics from lab-bound tasks to fluid, real-world action. With mobility, dexterity, and human-like training built-in, it’s the perfect platform for researchers wanting to teach robots more than just how to pick and place. Whether it’s cooking shrimp or tidying up, Mobile ALOHA is your next leap in robot learning—one human demo at a time.

Supercharge your production with CORLEO Kawasaki

Supercharge your production with CORLEO Kawasaki